Strategi Engineering Design Solutions

111111

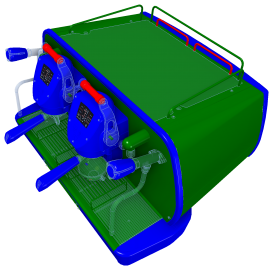

Solid Edge

Affordable, Easy to Use Software for Product Development

Solid Edge is the most affordable CAD Software for Design and Manufacturing Processes. Solid Edge can be utilized as a one stop solution for Product Development of Product Domains like Machinary, Process Equipment. etc

Capabilities

Create new design iterations at a click of a button

Automatically generate new designs based on defined parameters and rules with the embedded Solid Edge® Design Configurator software. Solid Edge Design Configurator is a design automation application that adds rule-based automation to a user’s familiar Solid Edge mechanical design environment. Completely embedded in Solid Edge, it enables the quick customization of products based on design parameters and rules. Rule-based automation can boost productivity and design speed.

Seamlessly integrate CAD geometry

CAD Direct, a new built-in 3D design capability, improves productivity when working with geometry from popular computer-aided design (CAD) systems. Insert files directly into a Solid Edge assembly without the need to translate the file separately, maintaining associativity. Data is stored in the 3D design assembly file, preventing data duplication.

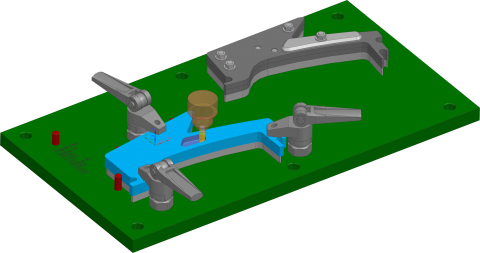

Experience 2.5 axis milling

Solid Edge Classic, Foundation and Premium now include fully functional 2.5-axis milling capabilities for customers with active maintenance. Fully integrated with Solid Edge, Solid Edge CAM Pro 2.5 Axis allows users to maintain full associativity with design data while instilling confidence with automated tool path creation and visualizations for optimized machining processes.

Don’t let complex assemblies slow you down

Solid Edge puts you at the top of your game with orders-of-magnitude performance improvement in large assembly modeling for the third straight year. Fast assembly open allows users to enter a preview mode in order to reduce the amount of data that is loaded. Multi-body assembly modeling mode is a new environment to model internal components within an assembly file. New component finder puts intuitive search of assembly components at your fingertips with auto-complete suggestive filters.

Leverage b-rep and mesh geometries in the same model without conversions

Unique hybrid model capabilities allow b-rep and mesh geometries to coexist in the same model for downstream assembly use, speeding workflows and making mesh models even more useful. Removing the need to convert mesh or b-rep geometry for them to work together reduces model development time.

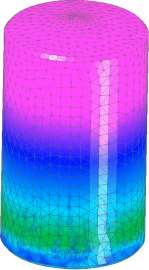

Accelerate the speed of simulation

New automated mesh generation processes in Solid Edge Simulation provide high-quality mesh with minimum effort, controlling mesh without the need for parameters. Simulation display performance, now up to 10x faster than before, optimizes load times for results data. Satisfy increasing demands for high performance and efficiency of hydraulic systems with a new hydrostatic pressure load type that determines the maximum and minimum pressure that is exerted by a fluid at equilibrium due to the effect of gravity.

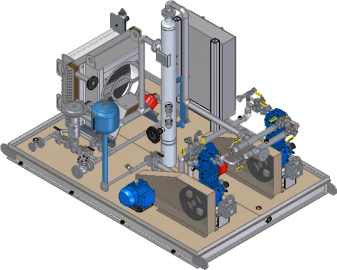

Improve the flow of piping system design

Introducing Simcenter™ Flomaster™ for Solid Edge software. Based on a leading 1D computational fluid dynamics (CFD) simulation tool for fluids engineering, this new product allows users to easily model and analyze the fluid and thermal flows in their piping systems. It automatically extracts 3D geometries to generate system-level models, which cuts the time required to build a simulation model by up to 90 percent. With built-in wizards, Simcenter Flomaster for Solid Edge is easy for novices to use, yet it is also appropriate for simulation experts with its advanced capabilities such as simulation of rapid dynamic events and pressure surge.

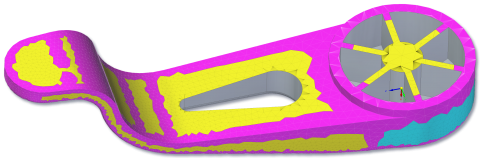

Generate a clear view of your design data

New built-in customized reports for Solid Edge, dynamic visualization, provides dynamic methods for viewing and sorting assembly parts and components. The visual reports are built on rules that are easily created with filters that resemble Excel spreadsheet software within interactive tables.