Strategi Engineering Design Solutions

111111

Tecnomatix

Tecnomatix for Plant Simulation

Tecnomatix is a digital manufacturing solution that enables Manufacturing Industries to Automate and optimize Production capacity and Capital investment. With Tecnomatix software, Industries can establish synchronization between product engineering, manufacturing and service operations to maximize production efficiency and realize innovation.

Output :

- Manufacturing process planning and management.

- Robotics offline programming and virtual commissioning.

- Human factors and ergonomics.

- Plant simulation and throughput optimization.

- Augmented and virtual reality.

Capabilities

Navigate Digital Twins of Your Production Facilities

Intosite™ allows you to create cloud-based 2D/3D/panoramic representations of a production facility, presented in its geographical context. This allows you to navigate through the facility in a simple and familiar way providing intuitive access to information from any IT system.

Intosite facilitates a virtual tour of your facilities using rich visualization techniques, with the ability to get relevant information by simply clicking on visual tags that are connected to PLM and other IT sources.

Commission Automation Systems Virtually

Tecnomatix virtual commissioning solutions let you debug automation control logic and PLC code in a virtual environment before downloading to real equipment. By simulating and validating your automation equipment virtually you can confirm that they will work as expected and significantly reduce system installation cost and startup time.

Perform Human-Centered Design and Planning

With Tecnomatix human modeling and simulation, you can improve the safety, efficiency, and comfort of your workplace environment using Jack and Jill virtual humans. Human-centered operations can be analyzed with lifelike models that can be scaled to match different population characteristics.

You can test design and operational aspects of a wide variety of human factors, including injury risk, timing, user comfort, reach-ability, line-of-sight, energy expenditure, fatigue limits, and other important parameters.

Configure the Layout of your Digital Factory

Design assembly lines, equipment and tool requirements in a 3D environment. Optimize factory space and maximize capital resource utilization by digitally configuring factory layouts.

Quickly design, visualize and optimize complete production layouts and easily associate them to manufacturing planning using a single system.

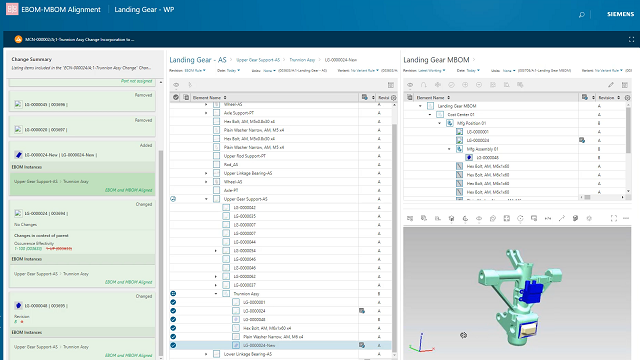

Synchronize Process Design to Deliver Better Plans

Tecnomatix and Teamcenter Manufacturing process design solutions allow you to associate and reconcile multiple configurations of product bills of material (EBOMs), manufacturing bills of material (MBOMs), and bills of process (BOPs). You can also validate manufacturing planning decisions by using advanced visualization and analytical tools.

Our solution allows design and manufacturing engineers to concurrently develop product and process planning definitions. This ensures that manufacturing constraints can be reconciled during product design, resulting in more efficient manufacturing plans.

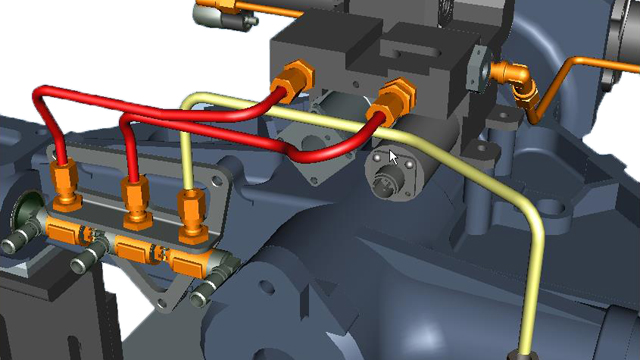

Conduct Assembly Simulation for Virtual Process Verification

Optimizing the assembly process upfront, prior to the start of production, results in more accurate manufacturing plans and improves time-to-volume-production. You can reduce your overall planning process time, shorten production setup, achieve faster ramp-up and deliver high-quality products right the first time by using assembly simulation to virtually verify all of the process operation steps and their details.

Efficiently author manufacturing process plans and effectively communicate them throughout your extended enterprise.

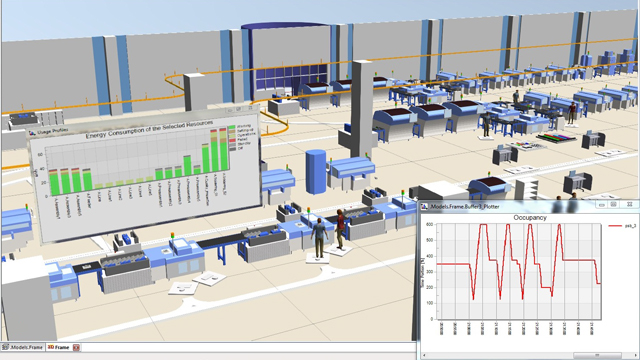

Optimize Production Logistics & Material Flow

With Tecnomatix logistics and material flow simulation, you can use discrete event simulation and statistical analysis capabilities to optimize material handling, logistics, machine utilization, and labor requirements. This allows you to quickly check for bottlenecks, validate transported materials, and view resource utilization over time for multiple process alternatives. Using stochastic tools with object-oriented and 3D modeling capabilities, you can increase your manufacturing accuracy and efficiency while improving throughput and overall system performance.