Strategi Engineering Design Solutions

111111

Simcenter 3D

Design Smarter Product Cycles with Simcenter

Test your product’s entire lifecycle with ease in a state-of-the-art simulation environment. Simcenter™ 3D allows you to optimize your design cycle and stay up to date with market demands for smarter products that integrate mechanical functions with electronics and controls.

Simcenter enables you to predict performance across all critical attributes of your design so you can get your products to the market faster. By utilizing a Digital Twin approach, Simcenter enables testing of your product virtually to help deliver innovations with greater confidence.

Capabilities

Acoustic Simulation

Acoustic software can help you conquer these challenges. Simcenter offers interior and exterior acoustic simulation within an integrated solution that helps you make informed decisions during the early design stages so you can optimize your product’s acoustic performance. A unified and scalable modeling environment combined with efficient solvers and easy-to-interpret visualization capabilities enable you to quickly gain insight into the acoustic performance of your product.

Aerostructures Simulation

Simcenter can help you meet shorter timelines and reduce structural analysis costs with the ability to perform end-to-end aerostructure assessment in a fully integrated environment. Eliminate mistakes and ramp up productivity with ready-to-use failure prediction methods and customize your solution by integrating your internal tools and IP to streamline your aerostructures analysis processes.

CFD simulation

Simcenter provides industry leading computational fluid dynamics (CFD) software for fast, accurate simulation of almost any engineering problem that involves the fluids, structures and all of the associated physics.

The real-world performance of your product depends on how it interacts with fluids, either gases, liquids or a combination of both. From designers to CFD engineers to researchers, Simcenter CFD simulation software allows you to predict the most complex fluid dynamics problems virtually and turn these insights into product innovation.

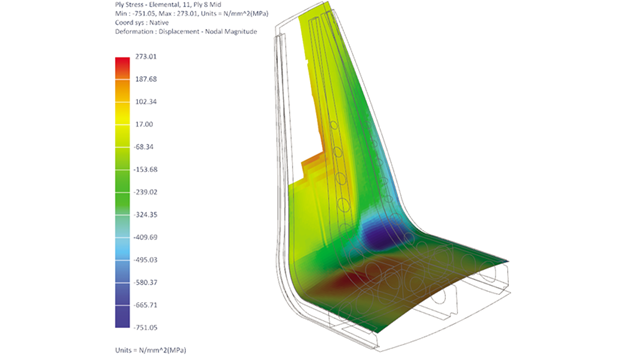

Composites

In the quest to make products lighter yet stronger, manufacturers are increasing their use of composite materials. It is also prohibitively expensive to create prototypes of products made from composites, so simulation must play a key role in the development of new products using laminate composite materials. Simcenter is at the leading-edge of composites analysis through continuous development of material models and element types. Simcenter speeds the entire process for simulating laminate composite materials through a seamless connection to composites design, accurate solvers and comprehensive post-processing.

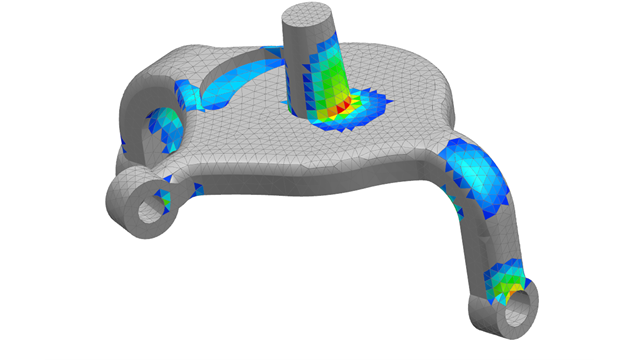

Durability and fatigue analysis

Undoubtedly the most challenging task for durability engineers is designing fail-safe components and systems in the most efficient manner. System parts with insufficient fatigue strength may cause permanent structural damage and potentially life-threatening situations. Mistakes can cause product recalls which negatively influence not only the product but the overall brand image. Shorter development cycles and ever-increasing quality requirements have stretched test-based durability approaches to the limits. Evaluating and refining the durability performance by simulating using durability software methods is the only valid alternative.

Simcenter durability software gives you access to state-of-the art fatigue analysis methods that enable you to perform fatigue life prediction analyses quickly and accurately accounting for realistic loading conditions.

Electromagnetic Simulations

Simcenter includes distinct low and high-frequency electromagnetic simulation capabilities for the unique demands in each domain. Expand your insight into the performance of electromechanical components, energy conversion, design and siting of antennas, electromagnetic compatibility (EMC) and electromagnetic interference (EMI). A range of dedicated solvers (time and frequency based, linear and nonlinear, finite and boundary element) offers a transformative CAE process, with simulations ranging from a fast, initial analysis to inherent realism for final verification.

Motion Simulation

Understanding the engineering performance is challenging for intricate mechanical systems, like in wing flaps or landing gear, sliding sunroofs or suspensions, or photocopiers and other mechanisms. Motion simulation uses multibody dynamics to calculate the reaction forces, torques, velocities, acceleration and more for mechanical systems. You can directly convert CAD geometry and assembly constraints into an accurate motion model or create your own multibody model from scratch. The embedded motion solver and robust postprocessing capabilities allow you to study of a broad range of mechanism behaviors.

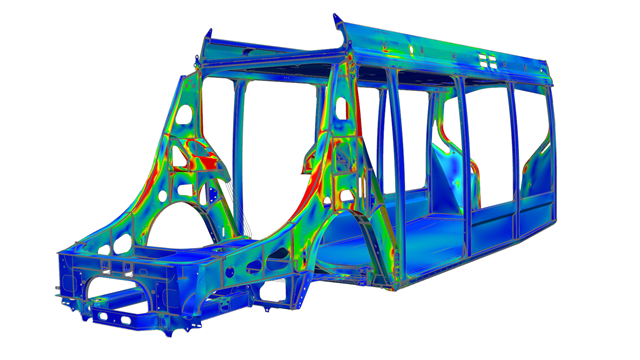

Structural Analysis

Understanding how a component or product assembly reacts under stress or vibration is critical in any industry. However, as products and materials become increasingly complex, engineers need tools that go beyond linear-statics analyses. Simcenter provides the structural analysis software you need to simulate a wide range of applications all within a single user environment. You no longer need one tool for linear statics, another to study fatigue, and yet another for nonlinear analysis. As a result, engineering departments can consolidate structural analysis tools, and you only need to know a single user interface.