Strategi Engineering Design Solutions

111111

Star CCM+

Design Smarter Product Cycles with Star CCM+

Test your product’s entire lifecycle with ease in a state-of-the-art simulation environment. Star CCM allows you to optimize your design cycle and stay up to date with market demands for smarter products that integrate mechanical functions with electronics and controls.

Star CCM+ enables you to predict performance across all critical attributes of your design so you can get your products to the market faster. By utilizing a Digital Twin approach, Simcenter enables testing of your product virtually to help deliver innovations with greater confidence.

Capabilities

Design Exploration

To stay ahead in the innovation race, engineers need to be able to quickly predict the outcome of design changes on the real-world performance of their product. Engineering simulation provides an excellent way for designers and engineers to cost-effectively evaluate how their products will perform under expected operating conditions.

Design exploration software takes simulation to the next level by allowing users to determine appropriate values of variables that yield product designs that result in exceptional performance.

Electrochemistry Simulation

Our comprehensive electrochemistry simulation suite includes the building blocks of electrochemistry, various degrees of fidelity, tailor-made electrochemistry models, multiphase electrochemistry and design exploration capabilities.

With electrochemistry simulation in Simcenter, you can achieve decreased resistances, minimize degradation and attain higher deposition/etching rates. This lowers design/operational/maintenance costs while ushering in innovative new fuel cell types, operating ranges and novel processes and materials.

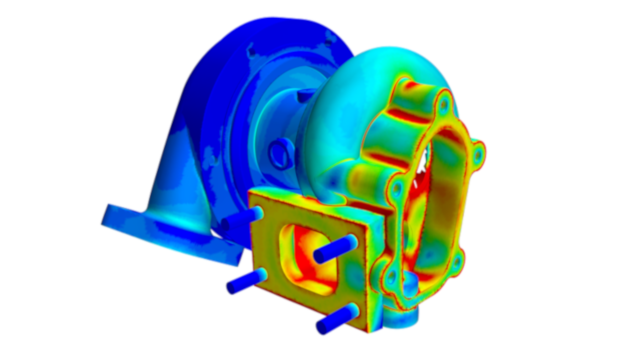

Thermal Simulation

Thermal management is a major consideration for a wide range of products, including industrial machinery, automobiles and consumer electronics. The objective of any thermal management solution is to maintain a product’s temperature within a range that is optimal for performance. Accomplishing this may require the removal or addition of heat, either passively or in an actively managed fashion, and this can be evaluated using thermal simulation software.

Simcenter includes comprehensive, best-in-class thermal simulation capabilities that can help you to understand the thermal characteristics of your product and subsequently tailor your thermal management solution for optimal performance.

Multiphase Flow Simulation

Real-world engineering problems cover multiple flow regimes across stratified, dispersed, discrete, films, etc. To date, there is no single multiphase model that can cover all regimes, however, Simcenter provides a comprehensive range of models which can be used together to cover many flow regimes including the transitions between them. Predict and understand real-world behavior of your products by simulating multi-regime, multi-scale multiphase flows.

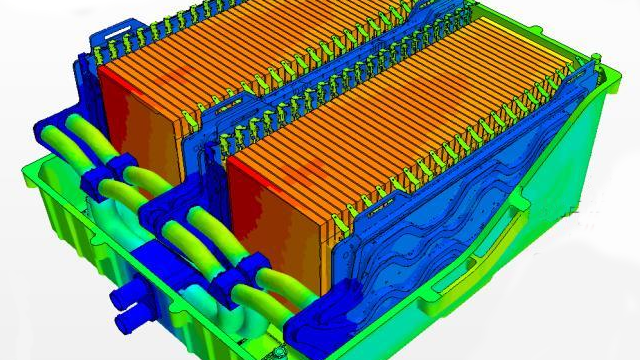

Battery Simulation

Digitally validate Li-ion cell design including geometrical cell specifications and cell performance with battery CFD simulation. Extensive components of a battery cell are available, as well as a material database to support the user in model development using CFD analysis.

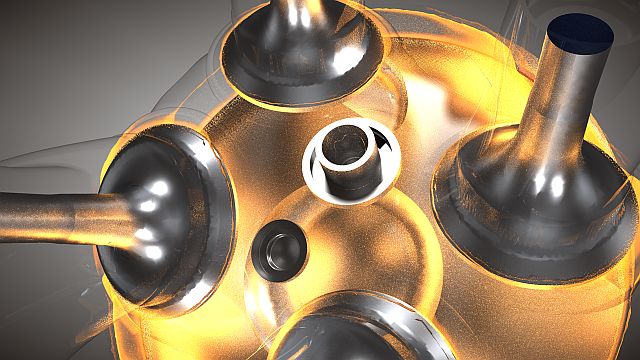

Engine Simulation

Engine simulations involve moving components, multiphase flow, combustion and heat transfer. You no longer have to be an expert user to simulate internal combustion engines: using an application-specific workflow and simplified interface allows you to set up engine simulations quickly and easily. Expert users can use those simulations as the starting point for performing more complicated multiphysics engine simulations that exploit the full range of Simcenter STAR-CCM+ simulation capabilities.

Solid Mechanics

Almost all real-world engineering problems ultimately depend on the interaction between fluids and solid structures. Simcenter STAR-CCM+ offers both finite volume (FV)-based computational fluid dynamics and finite element (FE)-based computational solid mechanics (CSM) in an easy-to-use single integrated user interface. Using this approach you can solve static, quasi-static, and dynamic problems including those with nonlinear geometry and multiple parts using bonded and small sliding contacts.

Reacting Flow

Simcenter delivers a comprehensive suite of reacting flow and emission models, covering a wide range of applications. It enables tight coupling between reacting flow models and heat transfer, radiation, multiphase reactions, and surface chemistry. Our reacting flow models help understand and optimize flame shape and location, minimize solid component temperatures, reduce emissions and maximize performance efficiency. You can predict and understand flame dynamics, heat transfer, thermal wear, emissions, yield, conversion, selectivity, and undesirable conditions to accurately capture real-world physics of your designs.

Particle-Flow Integration

Particulate flows in engineering exist everywhere – fluidized beds, cyclone separators, coating, conveyors, roasters, and more. Whether lean or dense particle flows, Simcenter is the first CAE tool to have full particle-flow integration to maximize particle efficiency and distribution, minimize energy consumption, avoid excessive wear and abrasion and optimize the overall performance.

By simulating realistic particle shapes accurately with proper particle motion and contact, engineers can ensure particulate performance. Unlike other tools, a single license is enough for resolving coupled flow and particulate physics, reducing expensive software and testing cost.